Table of Contents

Introduction

The product development life cycle includes creating ideas, conceptualization, product design, direct and simulated testing as well as product manufacturing. At each stage, many colleagues involved in the project must communicate with each other, documentation must be developed regularly and updated collaboratively, and regulations must be met. It is important to use a well-organized approach to achieve success during product development.

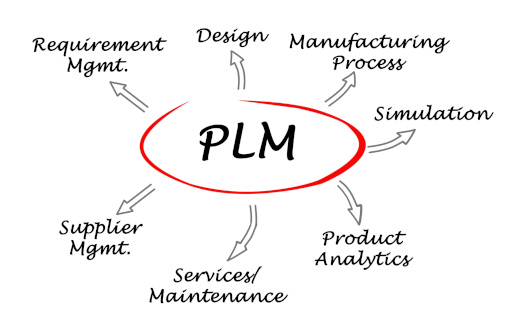

Product Lifecycle Management (PLM) refers to the management of people, processes and data throughout the product design, engineering, manufacturing and service of a product. It consolidates systems and builds a logical data structure. PLM allows distributed organizations to work as a single team on all tasks related to product design, manufacture, support and utilization. PLM helps to meet all the process requirements through every stage of the product lifecycle.

Generally speaking, all product development projects need some kind of process management system. Software solutions may not be the only management solution however. Solutions could include a series of guidelines for communication, documentation, and data analysis, but the right technology increases productivity. PLM software facilitates the process considerably.

What is PLM Software?

Product lifecycle management software is the software used to manage the product development process, from idea creation, through design, testing and manufacturing to selling, service and product disposal.

Product lifecycle management software is the software used to manage the product development process, from idea creation, through design, testing and manufacturing to selling, service and product disposal.

PLM systems integrate the data, people, processes and business software involved in the product development process. It provides a single platform to access all the necessary information and share it with multiple teams. The key element of each PLM system is a data model and tools supporting data management.

This kind of software streamlines product development processes and helps to overcome increasingly complex challenges on the way to a faster and more successful product development and (less) market introduction.

Who Uses PLM Software?

All the companies engaged in the creation of a product can benefit from the use of PLM software. Design teams use these tools to store details of their designs and work on them together. Product manufacturers use them to ensure that the products they build meet company standards. A product manager controls all the stages of the product lifestyle using a PLM system. PLM solutions can be applied to efficiently design and produce any product.

The companies who experience the following problems are even more likely to need a PLM system implementation.

Communication failures and complications cause delays and errors. If communication breaks down between the teams, at the manufacturing partners or suppliers, centralized PLM communication can help. It reduces to a minimum communication errors.

Regulatory requirements are hard to meet. With PLM, all the data and documents are stored in a centralized place making it easy to ensure that a product meets compliance requirements.

Expenses often exceed the budget. PLM systems allow you to monitor all the processes and expenses to see the project “big picture” so that you can identify where expenses can be trimmed without sacrificing quality.

Common PLM software features

All PLM features can be divided into groups by purpose:

Collaboration tools

These features make it easy for employees from different departments and businesses to work together. Collaboration tools are especially important for geographically dispersed teams or for companies that outsource manufacturing or parts of the product development process.

BOM Management

With PLM, you can create, redline, import, and export drawings, components, documentation and approved manufacturer and vendor information (AML/AVL). The information is structured and forms detailed, multi-level, hierarchical Bills of Materials (BOM).

Documentation authoring

While developing a product, each company generates internal and external product documentation. These may include user guides, assembly instructions, service manuals internal notes on product development, and other technical publications. The documentation may be required in multiple languages. Thus, a PLM should offer content authoring tools and allow for tracking of the iterations of each document.

Workflow and Change Management

Companies need to manage the changes during ideation, design, manufacturing, service, etc. PLM enables effective change management in various product development areas:

- product revisions and redlining,

- document versions,

- impact analysis,

- change ordering,

- workflow approval, other processes, including ECOs, CAPAs, etc.,

- link engineering to create closed-loop processes

- direct changes to pre-defined approvers and groups.

Compliance management

Most product companies are either subject to some level of regulation (e.g., environmental safety directives) or want to receive certification to follow industry standards. PLM will help to track compliance with standards like RoHS, WEEE, ISO, etc. Preparing for an audit also becomes much easier.

How PLM is different from PDM and PIM Software?

Product Data Management is usually a part of Product Life Cycle Management. The PDM software meets basic needs: it ensures that product data is correct, centralized and easily accessible by all involved teams. It is used mainly during the product development life cycle. The PLM has wider functionality, covering the whole product development process.

The Product Data Management (PDM) system is responsible for managing the digital product files that move through the PLM process. PDM is used to maintain a single version of every file, and track version changes.

Though, PDM won’t help with workflow management and other product development processes. This is where you need a PLM system. PLM software can be integrated with the PDM system to receive information.

Product Information Management (PIM) software has completely different objectives to PLM.

A PIM system is used to manage product information, but it is not related to engineering, design, and manufacturing, as PDM is. PIM focuses on marketing needs. It is a single source of data important for sales and marketing. It also helps publish product information across channels.

PLM can be a sourcing system for a PIM.

Benefits

The benefits of PLM arise from better communication and more efficient organization afforded by the PLM systems. It streamlines product creation, serves as storage for all product files, and empowers employees working on the project to make real-time decisions.

PLM software

- optimizes relationships along the product lifecycle and across organizations,

- speeds time to market,

- helps to meet cost and revenue targets,

- helps to improve product quality,

- maximizes the lifetime value of your product portfolio,

- drives the best revenues through repeatable processes.

Note, PLM systems provide maximum benefits when used as part of a holistic approach.

Top 10 PLM System Suppliers

The top PLM systems have all the common PLM software features mentioned above and offer other features and tools that facilitate the development process.

1. Upchain PLM

It’s a cloud PLM solution best for small and medium-sized companies.

Its main features are:

- 2D / 3D CAD viewer and markup,

- automated parts numbering,

- agile project management,

- project dashboards and KPIs,

- CAD plugins and API Integrations.

2. Arena PLM

Arena PLM is focused on designing and developing a quality product. This software is easy-to-use and has a great set of item-related features.

The main features:

- management of the manufacturing processes,

- accounting & finance reporting.

- production scheduling,

- shipping logistics,

- inventory management, etc.

3. Aras PLM

Aras PLM is an open-source system, so it can be customized for your needs. It’s a mature system, with a dedicated community.

The main features:

- planning of the manufacturing processes,

- configuration management,

- system engineering,

- PDM/PLM integration features,

4. SAP PLM

SAP PLM software makes BOM creation remarkably easy. It’s also easily integrated with ERP. SAP offers tutorials and arranges webinars to help users to understand the system and take maximum advantage of it.

The main features:

- centralized PPM (product portfolio management),

- application technology functions and features,

- batch management,

- innovation management.

5. Siemens Teamcenter

An easy-to-use system with powerful change management features, easily integrated with CAD systems.

The main features:

- supplier management,

- manufacturing data and process management,

- schedule management,

- service lifecycle management,

- product sustainability.

6. PTC Windchill

This software is focused on innovation and the ability to work fast and accurately. Since Windchill was introduced onto the market, its architecture has been rebuilt, the interface has changed a lot and has become personalized and customizable.

The main features:

- multiple system data management,

- associative BOM,

- reliability management,

- advanced search options,

- quality management,

- cost management.

7. Autodesk Vault

Autodesk Vault offers three products: Vault Basic, Vault Workgroup, and Vault Professional. They differ in features and pricing. The basic version comes with a subscription to Product Design & Manufacturing Collection and is not sold separately. The Workgroup is the advanced version. The professional edition is designed for multi-site business system integration. All the versions offer the same basic data management features. The Workgroup edition has more common PLM features. However, it doesn’t support BOM management and ERP integration, as the Professional version does.

The main features of the Workgroup and Professional versions:

- task automation,

- projects and reporting,

- revision control,

- Microsoft Outlook integration

8. Oracle Agile PLM

This enterprise PLM solution offers powerful functionality to manage entire product value chains. At the same time, it’s easy-to-use and has a customizable dashboard.

The main features:

- quality management,

- portfolio management,

- cost management,

- Oracle product lifecycle analytics.

9. Propel

The Propel company offers integrated Product Lifecycle Management (PLM), Product Information Management (PIM) and Quality Management Systems (QMS) solutions built on the Salesforce platform.

The main features of the PLM solution:

- audit management,

- complaint management,

- risk management,

- quality management.

10. Infor CloudSuite PLM

This is an easy-to-use and affordable PLM software for small to medium-size businesses. Infor CloudSuite PLM can be easily integrated with the enterprise resource planning (ERP) system.

The main features:

- optimization of design reuse from qualified suppliers,

- formula optimization,

- global labeling compliance,

- batch creation and updating of materials,

- coordination of new product introduction

Other popular PLM systems are Bamboo Rose, Dassault ENOVIA, CMPRO, Yunique PLM, Kalypso PLM, FusePLM.

Conclusion

You can facilitate the development of a new product by using PLM software. The product development life cycle includes many processes that are covered by common features of systems, such as collaboration tools, BOM and CAD management, documentation and compliance management. Popular solutions like Arena, Upchain, and Aras PLM offer advanced features. PLM systems reduce the time to market, help to stay within the budget, optimize relationships across organizations, and have a positive impact on the product quality. You should choose a PIM system, to improve your product marketing and the quality of the product information for your sales department.

We hope this research will help you to make better decisions and choose the best PLM software for your company. Take a look at AtroPIM, if you are also interested in a PIM software.